How Budapest Became Schneider Electric’s European Nerve Center

2023. 10. 04.

Can one single switchgear cause as much air pollution as driving a car 200,000 kilometers? Unfortunately, yes, but Schneider Electric, the leader in digital transformation of energy management and industry automation has something to offset that potential harm thanks to its HIPA-guided smart factory that broke ground earlier this year in Hungary. The Hungarian operation has been gaining on strategic significance for many other reasons too, not least because European procurements worth EUR 2 billion a year is coordinated from the Budapest hub. An in-depth report on why that matters to the company and the Hungarian economy.

The gigantic fish tank by the reception projects tranquility and harmony with fish of all kinds of colors going about their business in slow motion. Casually dressed young staff members, in turn, set a super vivid atmosphere against the backdrop of a truly state-of-the-art office environment. One small group that passes by converses in laid-back French – hardly a surprise given that Schneider Electric Hungary is the third largest company with French roots in Hungary.

The Budapest HQ that is home to some 800 employees looks busy, although it is the middle of the summer vacation season, and thanks to the hybrid work scheme presence is needed just three days a week. Colleagues are still free to show up in person more often since the company’s human-centric approach encourages them to take advantage of the power of networking. And that is what the office is for.

Being an ambassador of treating employees as valuable assets, Head of the Global Supply Chain (GSC) Hub and Procurement Director Márton Oltvai strongly believes in those close personal ties. As he explains, colleagues are not numbers in an excel chart, but an investment with true value. “In order for Schneider Electric’s global staff of 130,000 to cooperate smoothly, with a little exaggeration, everybody needs to know everybody. If you write an email to someone, they will have a totally different attitude towards your issue if they know who you are,” he says.

Hub power

Hungary plays a key role in the global strategy of the French behemoth. It has been present here since 1991, and by now it has four operational factories and a regional logistics center in the country. The fifth plant, a smart factory in Dunavecse broke ground earlier this year under a HIPA-guided investment of EUR 40 million. On top of that production capacity expansions totaling over EUR 15 million are also underway in Zalaegerszeg and Gyöngyös.

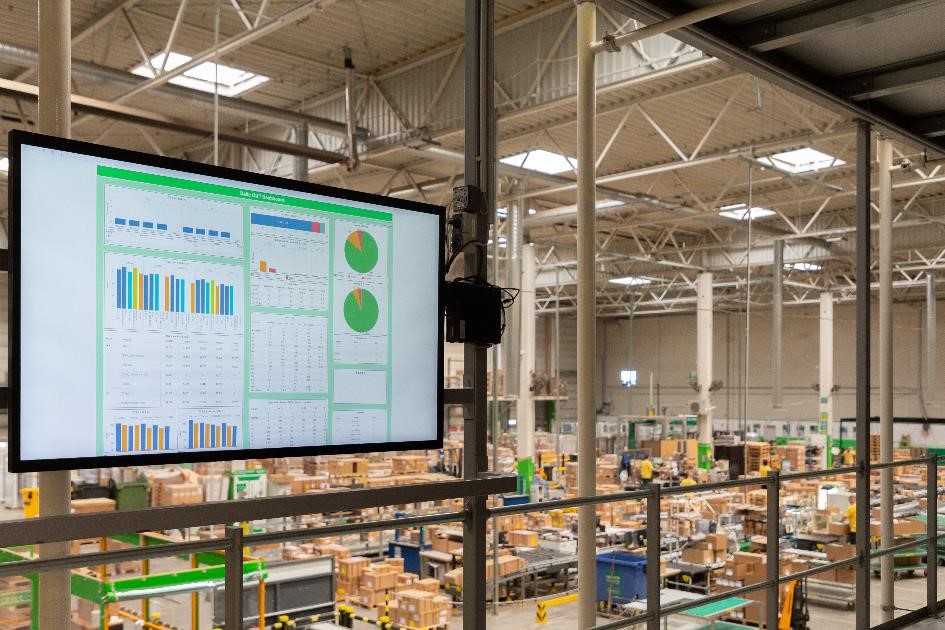

Now, apart from delivering cutting-edge solutions, Schneider Electric is rather known for its expertise in the field of energy management and industry automation. Lesser known is the fact that not only its commercial, sales and customer service center as well as the European HQ of its energy and sustainability service center are located in Budapest, but so is its regional procurement center. The latter has been growing in significance so much that by now procurements of 48 European factories in value of EUR 2 billion and corporate relations with up to 10,000 suppliers are coordinated from here.

As part of his job in terms of the GSC Hub coordination, that is what Oltvai is in charge of managing, too. Established in 2017, the Budapest GSC hub has 110 colleagues on board, and on the corporate level it has no longer a support function, but rather a business function. The actual reason for setting it up, though, was the idea of becoming ‘globally local’.

“We wanted to serve European factories from the continent and enhance security of supply which simultaneously supports sustainability,” Oltvai says. Covid demonstrated what a useful step this turned out to be, and it was because of this concept why Scheinder’s European plants could remain operational during the pandemic.

HIPA CEO István Joó also considers the Dunavecse investment significant since it is of symbolic nature in terms of French-Hungarian bilateral relations. The latter are of key importance for the purpose of investment promotion as evidenced by the fact that since 2014 up to 36 HIPA-guided FDI deals have been closed, whereas bilateral trade volume increased by 68% between 2010 and 2022, Mr. Joó points out.

the CEO notes.

Pandemic-induced creativity

Severe supply chain disruptions forced global corporations to switch into creative mode. Shippers that couldn’t find containers are now making their own, OEMs such as in the automotive industry buy mines, others sign strategic agreements with chipmakers. Schneider Electric wasn’t just sitting and waiting, either. Some 8,000 factory staff in Europe only needed fresh masks every four hours which led the company to invest in its own mask production line. Furthermore, skyrocketing shipment prices turned the entire concept of warehouse stocking upside down, so on occasions half- or full-year volumes were ordered in one go.

But supply chain disruptions also served as drivers of innovation. Take copper of which use is set to rise fast in the wake of electrification, but since supplies are scarce and likely to run out completely within decades, Schneider Electric started developments that aim at replacing it with aluminum.

No sign of slowing down towards net zero

Sustainability takes center stage in the corporate strategy. For one, the Zero Carbon Project aims to cut 50% of operational carbon emissions from the top 1,000 suppliers by 2025. And the effort is going to plan. According to Oltvai, 90% of those suppliers have already exceeded the 50% mark. Important to note that carbon emissions are measured against euro revenues meaning that in case revenues go up, the expected emission cuts must be calculated accordingly. “Market players take it ever more seriously to source goods from those that comply with sustainability requirements,” Oltvai points out, while adding that 200-plus colleagues are engaged in the field of sustainable business in Budapest.

The French-rooted giant is open to work with Hungarian suppliers as well. That is why it teamed up with the French Chamber of Commerce and Industry in Hungary to find potential partners. By now three local companies have joined the Schneider Electric supplier network that get all the support needed to go down the path of sustainability.

“We provide in-house automation solutions for them if needed,” Oltvai names a concrete example stressing that in the case of Hungarian suppliers what counts is commitment. Accordingly, a declaration of intent is signed, and continuous reporting is expected to prove the measures taken in the right direction. Stakeholders also have the opportunity to access a free online course to improve their related practices. No wonder 2021 saw Schneider named the world’s most sustainable corporation by Corporate Knights.

They practice what they preach

Schneider’s presence in Hungary of over three decades speaks for itself as it clearly signals a long-term commitment towards our country. Oltvai believes that there is still enormous knowledge base here that can be built upon where close cooperation with universities is key. Being a lecturer himself, he practices what he preaches.

“We aim to use this knowledge for the purpose of digital transformation, part of which is automation,” he says. The expert further stresses the significance of intensifying focus on R&D, and the establishment of the hub was a key step in this direction.

And the economic conditions for development look rosy all in all: Hungary offers exceptional stability and continuity which is coupled with competitive labor costs. “We need to put all our resources into training new generations of specialists who understand automation and can drive research and development. That is key to our future success,” he concludes.

Schneider’s goals luckily match those of HIPA’s investment promotion strategy that prioritizes projects that create high-value added jobs. Last year alone 25 such deals were announced in the field of BSC, ICT and R&D to create 2,500 workplaces. Apparently, Schneider Electric has found the right spot to make its objectives come true.